Free Book from Diesel Engine Management “Systems and Components” Bosch

Diesel technology has shaped the automotive industry for more than a century, and Bosch Diesel Engine Management Systems and Components remains one of the most respected references in the field. For over 75 years, Bosch has been a pioneer in diesel fuel injection technology, leading innovation in automotive diagnostics software, ECU programming tools, and vehicle safety systems.

This free book is not just another manual—it is a comprehensive diesel engine repair manual that covers everything from the history of diesel engines to modern Common Rail injection systems, emission control, fault diagnosis, and Electronic Diesel Control (EDC). Whether you are a professional mechanic, automotive engineering student, or simply an enthusiast, this guide is an invaluable resource.

In this article, we will walk you through the content of the Bosch book, highlight the most important systems and components, and provide a free download link at the end.

Why Bosch Diesel Engine Management Matters

Bosch has set global benchmarks in diesel technology since the 1920s. Their innovations have shaped how vehicles run today, including:

- High-Pressure Fuel Injection – From inline pumps to modern Common Rail systems.

- Electronic Diesel Control (EDC) – Integrating software and electronics with traditional mechanics.

- Emission Control Solutions – Reducing pollutants through optimized injection timing and after-treatment.

- Diagnostics and Maintenance – Fault detection and troubleshooting with advanced automotive diagnostics software.

👉 For related reading, check our guide on Automotive Engine Repair and Internal combustion engines.

Key Topics Covered in the Bosch Diesel Engine Repair Manual

The Diesel Engine Management: Systems and Components book is structured into chapters that progressively build your understanding of diesel technology.

1. History and Areas of Application

- Evolution of diesel technology from mechanical pumps to electronic control.

- Uses of diesel engines in passenger cars, trucks, agriculture, and industrial applications.

2. Basic Principles of Diesel Engines

- Compression ignition explained with diagrams.

- Differences between diesel and gasoline engines.

- Efficiency advantages of diesel engines.

3. Fuel Properties and Quality

- Impact of fuel cetane number.

- Fuel filtering and water separation.

- Biodiesel and synthetic fuels.

4. Diesel Injection Systems

- Inline Pump Systems – Traditional but reliable.

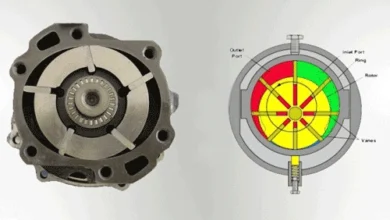

- Distributor Pumps – Compact for small engines.

- Common Rail Systems – High-pressure injection with precision.

- Unit Injector Systems (UIS/UPS) – Combining pump and injector in one.

5. Injection Nozzles and Components

- Design of pintle, hole, and multi-hole nozzles.

- High-pressure durability.

- Wear and tear troubleshooting.

6. Electronic Diesel Control (EDC)

- The integration of ECU programming tools with engine management.

- Real-time monitoring of injection timing and fuel quantity.

- Error code detection and troubleshooting.

💡 Related article: Sensors and Actuators in Modern Cars.

7. Fault Diagnosis and Testing

- Role of automotive diagnostics software such as Bosch KTS, Autel, and Launch.

- Using multimeters, oscilloscopes, and scan tools.

- Common diesel faults: misfiring, smoke, power loss.

8. Emission Control Legislation

- Euro 1 to Euro 6 standards explained.

- Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR).

- Importance of AdBlue in NOx reduction.

9. Low-Pressure Fuel Supply System

- Lift pumps, fuel filters, and lines.

- Cavitation and leakage problems.

- Preventive maintenance tips.

Benefits of Using the Bosch Diesel Engine Repair Manual

- Comprehensive Learning – Covers both theory and practical repair guides.

- Diagnostic Help – Learn how to use automotive diagnostic tools effectively.

- Cost Savings – Troubleshoot and fix issues before visiting a workshop.

- Professional Training – Perfect for technicians, trainers, and engineers.

- Future-Proof Knowledge – Updated with Common Rail and EDC systems.

Internal Links for Better Learning

Frequently Asked Questions (FAQ)

Q1: What makes the Bosch Diesel Engine Management book unique?

A: It combines history, theory, and hands-on repair methods, making it both an educational and practical diesel engine repair manual.

Q2: Can beginners use this book?

A: Yes. The content is structured from basic diesel principles to advanced topics like ECU programming tools and automotive diagnostics software.

Q3: Does the book cover emission systems like DPF and SCR?

A: Absolutely. It explains DPF cleaning, AdBlue usage, and compliance with Euro emission standards.

Q4: Is the book suitable for modern Common Rail diesel engines?

A: Yes. It covers both classic and modern Bosch Common Rail injection systems.

Q5: Where can I download the book?

A: Scroll down to the Download Link section below.

Conclusion

The Bosch Diesel Engine Management: Systems and Components book is a must-have for anyone involved in diesel repair, diagnostics, or engineering. From the basics of compression ignition to advanced automotive diagnostics software and vehicle safety systems, it serves as a complete guide.

By studying this diesel engine repair manual, you gain practical knowledge that can save costs, improve performance, and ensure compliance with emissions legislation.

👉 Download your free copy today and take your automotive skills to the next level.

📥 Download Link

Download Bosch Diesel Engine Management Systems and Components (Free PDF)